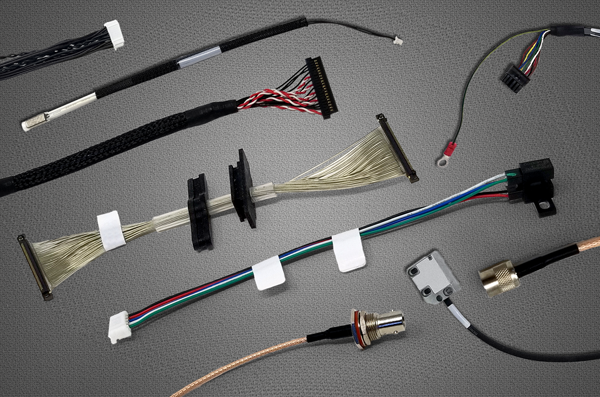

wire & Cable harness

design & source control services

Miraco applies its proven philosophies, using both foreign and domestic partners, providing our customers with a complete solution for new, or retrofit applications requiring a Flat Ribbon Cable Assembly or Discrete Wire Harness. As always, Miraco’s customers enjoy our wide range of benefits:

- In-house Engineering Design Team

- In-house Quality Control Lab

- Low Cost Value-Added Labor Center in Tijuana, Mexico

- Domestic partners who specialize in quick turn prototypes, production volumes and ITAR requirements

- Offshore partners where Miraco can transparently move the manufacturing to a low cost region while still maintaining quality controls

Design & Sourcing Capabilities

Together, We Can Connect the Inner Systems

Miraco’s mission to provide comprehensive flexible interconnect systems doesn’t stop with flat conductors. Miraco also provides design engineering, documentation, procurement, supply chain management and specialized added value services for discrete wire and flat ribbon cables. Like our other offerings, we focus on meeting the program goals of environmental, electrical, mechanical and cost objectives while providing a balanced solution.

ENGINEERING:

- 100 plus combined years of experience with round wire interconnect solutions

-

Knowledge of all major connector manufacturers, new product offerings and markets for wire harnesses

-

Complete engineering support takes the customer from design and testing to manufacturing

- Reverse engineering services available

- Full documentation on Miraco’s or customer’s format

SOURCE CONTROL MANAGEMENT:

- Miraco evaluates each application with a team of industry professionals to identify any areas of concern and formulate a comprehensive strategy to ensure the success of our customer’s program

-

Miraco creates, controls and provides complete “READY FOR MANUFACTURING” documentation and data packages

-

Miraco can seamlessly dual source applications to assure program delivery requirements and can frequently offer drop in replacement products that offer our customers a significant cost savings

-

Miraco exceeds conventional quality control practices to ensure all parts are built to print

-

Miraco has the systems and procedures in place to accommodate your preferred scheduling requirements such as: Kanban, JIT, Ship-to-Stock

MANUFACTURING SERVICES:

- Laser Services and Plasma Cleaning

- Folding, Wrapping & Forming

- Overmolding

-

Marking & Labeling

- Solder Assembly

- Electrical Testing

- Next Level Assembly (Box Builds)

MIRACO ADVANTAGE:

- IPC/WHMA-A-620 Specification Assemblies

-

Independent, unbiased design

-

Total Solution provider

-

Improve reliability while enhancing performance

-

Improved overall system cost

-

Improved design

- Improved manufacturability

- Improved time to market

Product Capabilities

MICRO-COAXIAL CABLE ASSEMBLIES

- RoHS Compliant Assembly

- Custom Reinforced Jacket

- High Density & High Performance

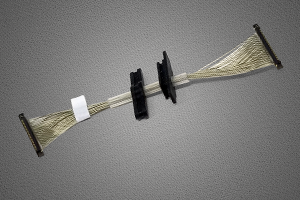

CUSTOM DISPLAY CABLE ASSEMBLIES

- LVDS System

- High Flexibility with Selective Flat Construction

- Connector Polarization

STANDARD DISPLAY CABLE ASSEMBLIES

- Compatible with Standard Displays and Drivers

- Quality Offshore Product

- Any Length, Any Termination

COAXIAL CABLE ASSEMBLIES

- Bulkhead, BNC & MCX Assemblies

- Crimped or Soldered Terminations

- Flexible or Semi-Rigid Assemblies

POWER CABLE ASSEMBLIES

- 300 Volt System

- Standard Power Wire Color Designation

- Insulated Fast-on™ Terminals

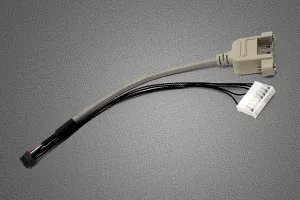

BOARD-TO-BOARD CABLE ASSEMBLIES

- Low Cost Systems

- Discrete Wire or Flat Cable

- Walled, Polarized or Latching Options