services overview

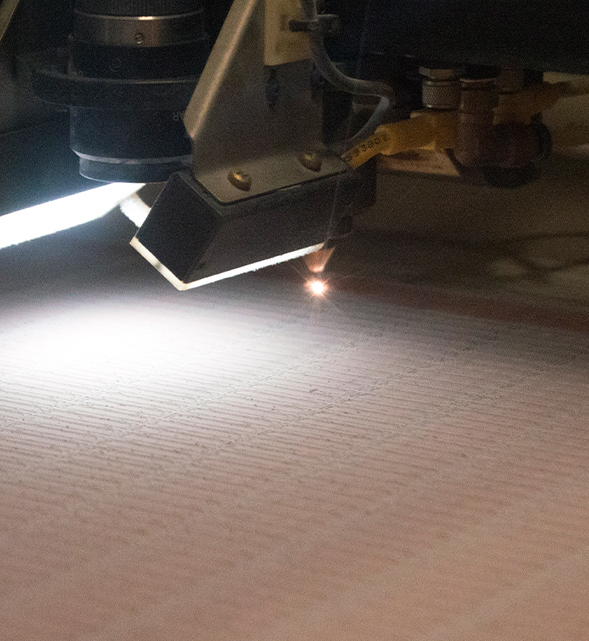

Quick Laser FPC Lasering

Miraco’s QUICK LASER TM service is the FPC (flexible printed circuit) manufacturer’s solution to finishing problems. Our team of dedicated professionals will perform your laser finishing and rework quickly and efficiently.

Unlike other job shops, Miraco’s team has the experience to handle the unique problems associated with finishing FPCs. Miraco’s specialized optic systems and operating programs solve processing issues, such as light refraction, bounce, shrinkage and inconsistent material thickness. Miraco’s QUICK LASER Service allows you to streamline manufacturing, increase production capacity and profit margins.

Benefits

When is Laser Finishing of Flex Preferred, and Why?

PROTOTYPE & LOW-VOLUME JOBS. GAIN THE COMPETITIVE EDGE.

- Quick Delivery – Turn prototypes faster using our 24-hour turnaround QUICK LASER finishing service

- Tooling Changes – Prototypes evolve, and with lasering program modifications, they cost a fraction of new tooling

- More Efficient – Free up your firm’s finishing, routing and engineering resources

LOW TO MID-VOLUME JOBS. LOWER COST, GREAT QUALITY.

Outlining Complex/Tight Tolerances – QUICK LASER gives you the tooling cost of a steel rule die, the lead time of routing, the accuracy and precision of a hard die without any of the associated deficiencies.

- Steel rule dies are not capable of obtaining the accuracy and precision of tight tolerance jobs

- Routing just does not cut it. The finish quality is poor and precision marginal

- Continuous outlining up to 44″

Reduce Tooling Costs – Don’t waste time and money getting a hard die for small volumes. Combine lasering with steel rule die cutting to get the best of both options without the deficiencies.

- Class A tooling is not economical for low to mid-volume jobs

- No die setup or first article inspections

- No expensive dies to purchase, store or maintain

ANY VOLUME. HAVE THE OPTIONS YOU NEED TO SUCCEED.

- Partial Outlining – Lasering only the critical portion of an outline (ex. ZIF End) and steel rule die cutting the rest is an easy method to finish higher volume parts without the expense and lead time of a Class A die punch

- Center Film Removal – Lasering is the only cost-effective, reliable way to remove center film.

- Pre-Clad Exposures – Now use pre-clad materials even for jobs that require reverse baring. Just laser it.

- Glue Squeeze-out – Problems maintaining critical exposures and windows because of glue squeeze-out? Eliminate the issue along with drill and routing steps with QUICK LASER finishing.

- Window Registration – If you need better than +/- .005 window registration, then you need QUICK LASER.

- Rework – Too much glue squeeze-out? Forgot to route a window? Don’t scrap it, save it! Pieces or panels, QUICK LASER can rework your job, saving you time and money.

Finishing Options & Features

Complete Finishing is the ideal option for prototype and complex production parts:

- Image, etch and laminate the panels and Miraco does the rest

- Eliminate interruption of manufacturing processes

- Even if your panel was not originally laid out to laser, Miraco can still meet your needs

Single-Sided Exposure of your FPC panel with QUICK LASER eliminates time and labor:

- Remove center film

- Eliminate glue squeeze-out on exposed areas

- Obtain tight tolerances (+/- .002″) between layer windows

Double-Sided Exposure of your FPC panel is reliable and cost-effective:

- Tolerances as low as +/- .002″ OL/SO

- Automatic compensation for panel distortion/shrinkage

- Intricate holes and details down to .006″

Outlining and Selective Outlining with QUICK LASER. Frees you from the limitations and cost of conventional outline tooling:

- Remove glue squeeze-out in plated through-holes and on surface mount pads

- Remove permanent nomenclature

- Correct drilling/routing errors

- Rework cover films registered incorrectly

- Remove solder mask

Board Repair and Rework with QUICK LASER. Eliminates the time and costs associated with scrapping and rebuilding your circuits:

- Remove glue squeeze-out in plated through-holes and on surface mount pads

- Remove permanent nomenclature

- Correct drilling/routing errors

- Rework cover films registered incorrectly

- Remove solder mask