INTERCONNECT SOLUTIONS

services overview

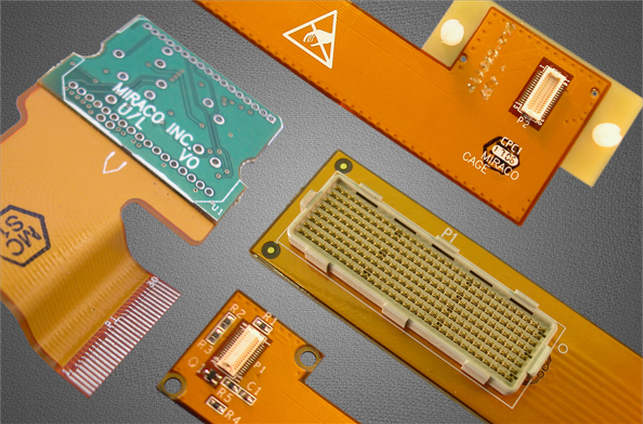

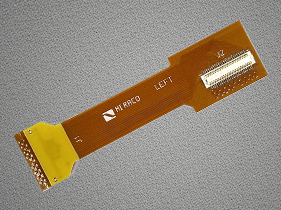

Flexible Printed Circuits Design & Source Control Services

Miraco's mission is to provide comprehensive engineering and global sourcing services specializing in flexible interconnect systems. Miraco provides design engineering, documentation, procurement, supply chain management and specialized added value services. We focus on meeting the program goals of environmental, electrical, mechanical and cost objectives while providing a balanced solution.

Miraco's engineering design team, specialized added value services, quality control lab and test equipment located in Manchester, NH combined with FPC manufacturers, both foreign and domestic, provides our customers with the complete solution that anticipates the issues encountered during the product life cycle:

- In-house Engineering Design Team

- In-house Quality Control Lab

- Domestic partners who specialize in quick turn prototypes, production volumes and ITAR requirements

- Offshore partners where Miraco can transparently move the manufacturing to a low cost region while still maintaining quality controls

Design & Sourcing Capabilities

Together, We Can Connect the Inner Systems

ENGINEERING:

- 200 plus combined years of design and manufacturing experience with all FPC and other interconnect solutions

- Knowledge derived from 30+ patents in the field of flex interconnects and connector technology

- Complete engineering support takes the customer from design and testing to manufacturing

- Full documentation on Miraco’s or customer’s format

SOURCE CONTROL MANAGEMENT:

- Miraco leverages its combined flex circuit purchases to achieve the best lead time and lowest material cost to benefit all our customers

- Miraco creates, controls and provides complete “READY FOR MANUFACTURING” documentation and data packages

- Miraco can seamlessly dual source applications to assure program delivery requirements

- Miraco exceeds conventional quality control practices to insure all parts are built to print

- Miraco has the systems and procedures in place to accommodate your preferred scheduling requirements such as: Kanban, JIT, Ship-to-Stock

- Assembly services provided by Miraco using approved and qualified contract manufacturers

MANUFACTURING SERVICES:

- Laser Services and Plasma Cleaning

- Steel Rule Die Outlining

- Class A Die Outlining

- Folding, Wrapping, Forming

- Overmolding Silver Shielding (360 Degree Coverage)

- Marking and Labeling

- Solder Assembly

- Electrical Testing

MIRACO ADVANTAGE:

- Independent, unbiased design

- Internally used process, competent technical understanding

- Total Solution provider

- Improve reliability while enhancing performance

- Improved overall system value

- Ideal for low temperature applications

- Safe for delicate electronic applications

- RoHS Compliant

- Machines in Miraco North and Miraco South

Product Capabilities

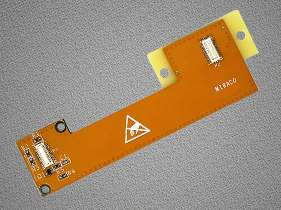

DISPLAY INTERCONNECT SYSTEMS

- 100 OHM differential pairs

- EMI control

- Active component assemblies with custom laminated stiffeners

INTERNAL DISC DRIVE

- Impedence controlled, 50 OHM single ended

- Highly flexible construction

- Accommodates various ZIF thicknesses

CUSTOM CONNECTION INTERFACE

- Flexible interconnect conversions available

- Configurable to any board terminator

- Custom connector designs available

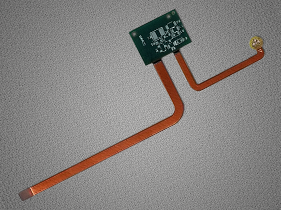

LOGIC INTERFACE

- Rigid-flex design

- Suitable for pick and place SMT

- Can be supplied in panel form with breakouts

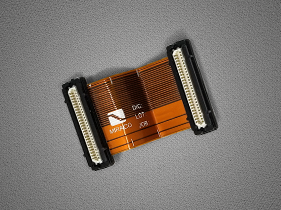

BOARD-TO-BOARD INTERCONNECT SYSTEM

- High density BGA connectors

- Isolated layer pairs for additional flexibility

- High density: Up to 10 layers

Design Formats

Autocad (DXF, DWG), Gerber (RS274-X) Solid Works (IGES, SLDPRT)

Panel Size

24" Maximum Width, 10' + Length

Covercoat Thickness

.005-up

Layer Count

1-18

Interconnect Assembly Types

Thru Hole

SMT, BGA, Hybrid FFC/FPC

Finished Hole Size

Compliant Pinned (rigid zone only) Via (A/R dependent)

0.018" (0.457mm)

0.008" (0.203mm)

0.008" (0.203mm)

Internal Features (Copper Weight Dependent)

Trace

Spacing

Spacing

0.003" (0.0762mm)

0.003" (0.0762mm)

0.003" (0.0762mm)

Materials

Polymide -= Standard Acrylic / Epoxy

Polymide - FR Acrylic / Epoxy

Polymide - AP

Polymide - FR Acrylic / Epoxy

Polymide - AP

Silver Epoxy Shielding

Soldermask

FR-4/21 & 24

Soldermask

FR-4/21 & 24

Copper Processing

1/4 oz. .032"

Impedance Single & Differential

+/- 10 % GHZ

Surface Finishes

HASL

OSP- Entek 106

ENIG

OSP- Entek 106

ENIG

Immersion Tin

Immersion Silver

Bright Tin

Ni/Au

Immersion Silver

Bright Tin

Ni/Au

Assembly Capabilities

Full Turn-Key

Thru-hole- Wave & Manual

SMT - Pick & Place

Wire-bond

Crimp

RoHS Compliance

Thru-hole- Wave & Manual

SMT - Pick & Place

Wire-bond

Crimp

RoHS Compliance

Custom Connection (interconnection forming)

Test Capabilities

Impedance Testing

Hi-Pot up to 5,000 VDC

2,000+ points per circuit

Insulation Resistance up to 500 VDC

Four Wire Kelvin .001 & up

IPC-TM-650 (Env-Mech Testing)

X-Ray Composition Analysis

Plating Thickness

Hi-Pot up to 5,000 VDC

2,000+ points per circuit

Insulation Resistance up to 500 VDC

Four Wire Kelvin .001 & up

IPC-TM-650 (Env-Mech Testing)

X-Ray Composition Analysis

Plating Thickness

Bed of Nails

Flying Probe

Flex Cycling

Environmental

Functional Test

LED's, Diodes, Resistance Capacitors

Flying Probe

Flex Cycling

Environmental

Functional Test

LED's, Diodes, Resistance Capacitors

Mfg. Standards

IPC-6013 Class I, II and III; Types 1-5

Mil-P50884 Types 1-5

AS9100 Certification

Mil-P50884 Types 1-5

AS9100 Certification

IPC-610

UL94VO

ISO 9001:2015 to 2018

UL94VO

ISO 9001:2015 to 2018

Laser Capabilities

Outline +/- 0.003"

Exposure single & double sided

Exposure single & double sided